THE BOOKLET OF TECHNICAL SPECIFICATIONS AS DIN 931 & DIN 933 IS ENCLOSED

MINI - ENCYCLOPEDIA OF STAINLESS STEEL

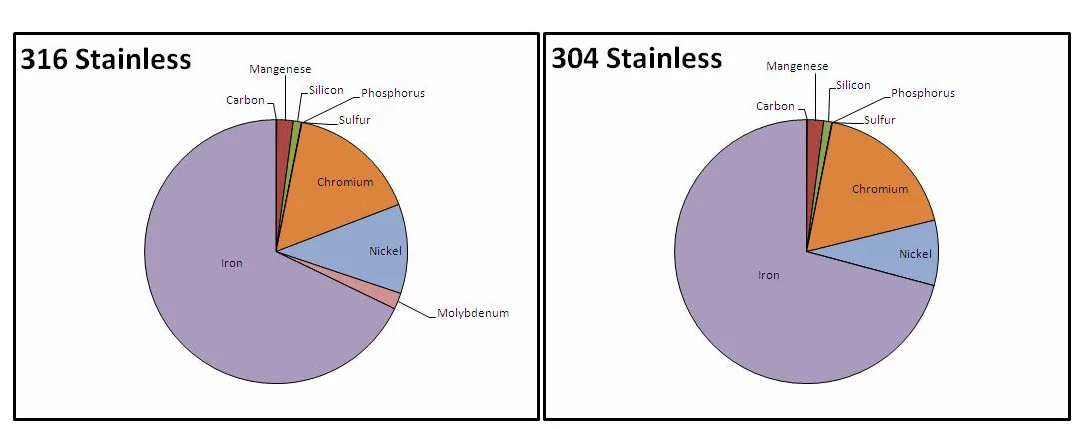

Refers to 300 series stainless, the most popular of stainless alloys accounting For 85 - 90% of stainless fasteners sold, named after sir robert willams austen, An english metallurgist, austenitic steel is a crystal structure formed by heating Steel, chromium and nickel to a high temperature where it forms the characteristics Of 300 series stainless steel. An austenite is a molecular structure where 8 atoms of Iron surround one atom of carbon, thus limiting the corrosive effects of carbon.

Austenitic fasteners gave high level of corrsion resistance in the stainless steel Family, cannot be hardened by heat treatment and are almost always non - magnetic. Sometimes heat and friction in cold forming can cause austenitic stainless to take Slight magnetism, but he corrosionresistant properties remain the same . Most Commonly used grade is termed as ss 304 grade.

Type 316 stainless has added nickel and added molybdenum . The molybdenum ( called Moly ) increases corrosion resistance to chlorides and sulfates, incldg.Sulfurous Acids in pulp industries . It has superior tensile strength at higher temperatures Compared to 304 , besides pulp and paper , typical industries using 316 Are listed below :

TYPICAL INDUSTRIES USING 316 GRADE FASTENERS

Carbon that breaks loose from its bond within the stainless solution when material Is heated between 800 - 1400 degrees. Under severe conditions , it can result in extra Oxidation and surface corrsion.

Adds strength to stainless steel , but also lowers corrosion resistance . The more carbon there is , the more chromium be added , because carbon offsets 17 Times its own weight in chromium to form carbides , thus reducing chromium Available for resisting corrosion.

Ablue white metal, chromium is the most important element providing corrosion Resistance in stainless steel. By adding 12% chromium to ordinary steel , stainless Steel is formed . Chromium offsets the corrosive effects of carbon found in steel And is the primary factor in the ability of stainless to form passive film on it's Surface providing corrosion resistance.

A measure of the resistance of fasteners to stress under elevated temperatures. At higher temperatures, a fastener can change in dimension under the same load , & is called creep.

Creep can cause the loosening of fasteners as temperature increases.

A variety of small or large disfigurations in a fastener such as pits , toolmarks , Voids, laps, folds and seams and inclusions.

Minor discontinuities are permissible in both commercial as well as special Tailormade fasteners and those made to various specs.

Where raw - material shaped like wire is pulled through a die to reduce its diameter To that needed for particular fastener being manufactured.

The ability of a fastener to deform before breaking ( for example an elastic would Be more ductile than diamond ).

Ductility is a measurement similar to elongation.

Stretching a fastener to the poin that it breaks. The percentage elongation at Rupture ( same as measure of ductility ) is determined by dividing the total length After stretching to the original length. Elongation decreases as the strength and Hardness increases.

As related to stainless steel fasteners , 300 series stainless is non magnetic In tis raw material condition . Cold working can sometimes induce traces of Magnetism in 300 series , depending on the severity of cold working and chemical Composition of stainless . A rise in magnetism is related to increase in tensile Strength and work hardening caused by the heat and friction of cold forming and Does not reduce corrosion resistance or cause any molecular change in austenitic Raw - material.

A higher portion of nickel can increase stability in stainless, thus decreasing work Hardening and any possibilities of magnetism . Many stainless specs allow 2.0 magnetic permeability which translates to low / medium magnetism.

A non - magnetic metal which improves strength and hardness.

N I cknamed moly, molybdenum is a metal added to 316 stainless steel , sharply Increasing corrosion resistance to chlorides and sulfates, especially various Sulfurous acids in the pulp industry. Molybdenum helps reduce hardness and Increases tensile strength at higher temperatures.

A metal added to 300 series stainless to provide corrosion resistance , increased Strength in both high and low temperatures and increased toughness in low Temperatures . Nickel lower the effects of work hardening , thus reducing traces of Magnetism caused by cold forming and making material flow more freely in Manufacturing.

Technically , passivating is the process of dipping fasteners into nitric-acid solution To rapidly form chromium oxide on the surface of the material , creating a passive Film that protects stainless from furthe oxidation . The pupose of passivation is To remove both grease left from manufacturing and traces of steel particles which May have rubbed off manufacturing tools on to the fasteners.

The major charateristic of stainless is its ability to form a thin layer of protection Called passive film on its outside surface . This film results from a continual process Of low oxidation , so oxygen from the atmosphere is needed for the passive film to Exist . Once formed it prevents further oxidation or corrsion from occuring . Even If chipped or scratched , a new passive film on stainless will form.

A test load that a fastener must undergo without showing significant deformation . It is usually 90% of the yield strength.

A common measure to compare the strength of a fastener.

It is the load needed to pull the fastener apart.

The amount of pressure required to cause permanent deformity.

Torque is the force used in twisting, such as tightening a fastener.Torsion strength Is the amount of force needed to twist a fastener apart . Both measures consider the Amount of pressure applied to the fastener and the length of the wrench used in the Application.

With the addition of 12% chromium to iron , stainless steel is formed . The chromium Protects the iron against most corrosion or red colour rust , thus the term Stainless steel . The ability of stainless to form a thin layer of protection on its Outside surface , called a " passive film " , is its most important characteristics in Preventing corrosion.

The overriding purpose of stainless steel is to provide corrosion resistance against ( a ) atmospheric conditions such as carbon dioxide , moisture , electricals fields , Sulfur , salt and chlorides compounds ( b ) natural and artificially produced Chemicals ( c ) extreme whether where cold temperatures cause brittleness and Hot temperatures reduce strength and increase corrosion.

| ( % Values in max.Unless otherwise stated ) | ||||||||

| Elements | C% | Si% | Mn% | P% | S% | Cr% | Mo% | Ni% |

| A2 ( 304 ) | 0.080 | 1.000 | 2.000 | 0.045 | 0.030 | 18 - 20 | NIL | 8 - 10% |

| A4 ( 316 ) | 0.080 | 1.000 | 2.000 | 0.045 | 0.030 | 16 - 18 | 2 - 3% | 10 - 14% |

|

All dimensional , mechanical and chemical properties are as per specified standards . The designation system comply with ' I s o ' 3506 standard . A270 donates a = austenitic Chromium - nickel steel , 2 = cold heading steel alloyed with chromium and nickel Normally called as 304 grade . 4 = cold heading steel alloyed with chromium , nickel And molybdenum . 70 = property class , ie : tensile strenght which is 10 times of the Denoted figure in n / mm 2 min. |

||||||||

Magnetism in Stainless Steel Fasteners

"The stainless steel fasteners I received stick to a magnet." This is one of the more frequently heard complaints at Fastenal Engineering & Design Support HQ in Winona, MN. Stainless steel fasteners being nonmagnetic is also one of the largest misconceptions amongst fastener users. This document will explain why most stainless steel fasteners are at least slightly magnetic and why many are so magnetic they are attracted to even weak household magnets.

As stated before, the microstructure of the metal is what gives the steel its magnetic properties. If the stainless steel chosen was austenitic, e.g. type 316, and a portion of the microstructure were changed to any one of the other four classes then the material would have some magnetic permeability, i.e. magnetism, built into the steel.

The microstructure of austenitic stainless steel can be changed by a process called martensitic stress induced transformation (MSIT). This is a microstructural change from austenite to martensite and the transformation can occur due to cold working (the process by which many fasteners are made) as well as slow cooling from austenitizing temperatures. After cold working or slow cooling an austenitic stainless steel will have an appreciable level of martensitic microstructure. Due to martensite being magnetic, the once nonmagnetic austenitic stainless steel will now have a degree of magnetism.

Cold Working

Though it may not seem like it, all fasteners can go through quite a bit of cold working prior to seeing service in the field. Cold working fasteners occurs in the wire drawing, forming, and thread rolling processes. Each of these processes will, typically, create enough martensite to produce a measurable degree of magnetism. See the Fastenal Engineering & Design Support videos on thread rolling and cold heading for more information.